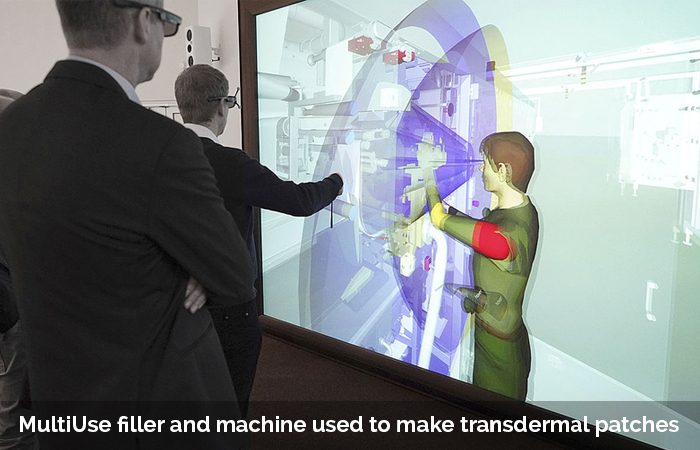

Coca-Cola and McDonald recently raided into the retail packaging that consumers are able to see inside their headset which can be considered as ‘Wicked Cool’ as the packaging equipment being displayed in VR so as to generate excitement by portraying the vivid color and animations of machinery in action captured from all different angles for cleaning and changing its parts. This experience was unveiled at PACK EXPO/Pharma EXPO. Optima Pharma and Optima Life Science presented the turnkey projects of flexible machines using virtual reality through on-site simulations at its “Virtual Reality Box.”

Optima Life Science also presented its new OPTIMA TDC125 machine which manufactures TDS short for transdermal patches and also oral filmstrips. The system operates intermittently in their simplest way and can also be operated in a more continuous mode with a great and high output in production series. Both intermit and the continuous working mode variants were shown illuionalistically in 3D.

Optima Pharma represented their pharmaceutical turnkey projects in 3 Dimensional using virtual reality which includes large systems which are implemented for filling and even sealing under the isolator. Turnkey projects can sometimes be as big as a house of a mid-size family. Here VR can be of a great help in having discussions with the customer while the project engineering is going on side by side. There are many features like Zooming into the machine, walking through it and so on. We now see that the Virtual Reality is taking care of the every single area. This has been made possible with more and more VR labs coming up in the world of technology.